|

|

The Governor This is often seen as a bit mysterious - and it is not an easy thing to get your head around. But I am glad I really looked into this - it is quite simple. Just does not quite function in the way I thought !

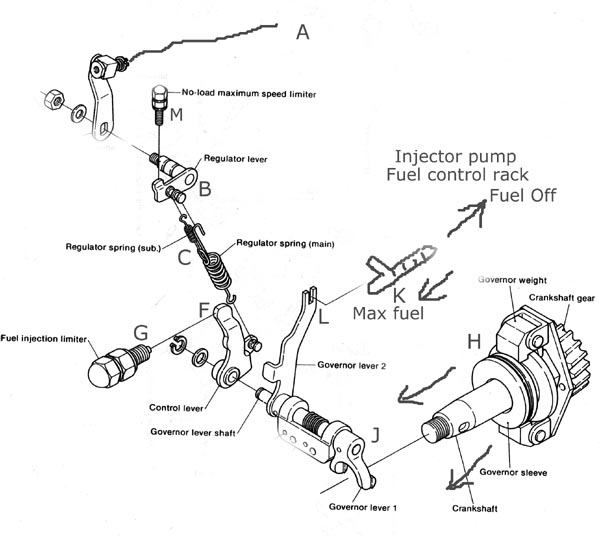

Basic operation - With the throttle lever off - resting on its idle stop ( not shown for clarity ) - the fuel control rack is fully ON - the lever F and lever L - is pulled up against stop limiter G - by the tension of the springs at C. When the engine starts to rotate - the governor weight fly the flange H fowards under centrifuge - and this pushes J, which forces L backwards - moving fuel rack OFF. If the tension of the spring is light ( as at idle position ) the lever L reduces fuel nearly off completely ( idle ) Pulling the throttle cable tightens the springs - so counteracts the force of the weights trying to reduce fuel - and a balancing act between the throttle spring and the governor centrifugal force takes place. This is how speed, load amd torque are controlled. Pretty smart really - just some levers and springs. The two springs are there for a simple reason. The main spring is too coarse for adjustment at idle speed - so they are doubled up, the small one working at idle speeds - then the main spring for the rest of the range. Now did you get that ? The fuel control rack at idle setting is fully ON ! Its a bit odd ! If the big spring broke - you would just have idle speed, no more. If that small one broke as well, it would stop. The throttle lever merely adds tension to the throttle spring - ie at idle with the engine off, throttle spring is 'lightly' holding the fuel control rack fully open. At full lever throttle - its holding it fully open with a much stronger force on the spring. Hence - when the engine starts - and the governor tries to close the fuel rack, you get more speed as it takes more pressure to offset the throttle spring. More pressure come from more centrifugal force at the governor weights. A balancing act between throttle spring and governor cetrifuge force - all carefully adjusted to suit the torqu, speed etc and fuel needs. Its really not complicated - but - it does not work the way I thought ! I have a lot of headache sorting this one out ! The Limiter This is just a max fuel position stop - but it has a sort of damper spring in it, with a pin, so as to allow the engine to exceed the stop under certain forces. Sort of like a power 'shock absorber'. But at heart it just a stop screw. It factory wired to stop people messing with the max injection setting. The No Load limiter M. This is simply a stop - again tamper proof - that limits the max phyical travel of the throttle lever. Straightfowrd - acts as the max tension one can put on the throttle spring. Maybe - and I'm not recommending it - on very old engines where the main spring is maybe worn - it might be a help to loosen this screw a touch. You can then put more tension on the htrottle spring at max ?

The Stop control I left it off for clarity. It basically completely over-rides the small tension that is on the throttle spring at idle, so governor has 'no tension against it' and closes completely. As soon as its stopped - the fuel control rack moves back to fiully ON.

The Start spring - between lever L and J - ? This one is a little more mysterious - but I think it just takes up the slack when the engine is at rest - so the fork ends are in contact with the governor thrust plate. I think ? - its a very weak spring - wound around like that. I think even the Yanmar workshop manual writers hardly understood the system - their desription did not help me much - but a very good look at the drawing and a careful read of the injector pump max min settings did sort of help. It took a lot of convincing to accept that max fuel was indeed 'fowards' on the rack. It is - I looked at a breakdown drawing of the injector pump to convince myself ! So - really this is a simple system with little to go wrong. Two springs - and a moving bob weight. All enclosed and covered in oil - so no rust or crud. Thinking about how it actually works - and that the max throttle can only be obtained by raising the tenson in the spring - it wuld not go amiss on an old engine to replace the main spring. Not easy to do I think without having the timing cover off. Bear in mind - if you ever have trouble with the springs, the injector pump is easy to remove - just three bolts and lift out - and it leaves a sizeable hole in the top of the timing case. It may well be possible to replace the springs through there - if you stick a blue Jay cloth on your head ! On the subject of timing covers - I did notice when working on the injector timing that the main crank pulley is drilled and tapped M8 with four holes. So you can get in there with an easy flush made puller plate - to pull the crank pulley. Should then be ale to drop the timing cover in situ - maybe ! If you ever have one off - then new springs are a must. I did check on the parts catalogue - the big spring is about £9 the smaller about £ 6 ( for Yanmar thats peanuts ! ) One may be able to change them with the Injector pump out ( easy to do ) Also bear in mind the throttle lever 'pivots' on a stud going through the timing case at the side - with a small O ring on it for oil leakage - and a bolt on the outer side. So - the lever spigot would release - 'inwards' - and the prings hang on this, so it would release the tension - and amaybe make it more feasible ! The little spring attaches to the upper portion of the big spring - and I think it might be difficult to set them up right working like that. ALSO - anything you drop goes straight down to the bottom of the timing case - and would HAVE to be fished out. Lots of important and expensive moving gears in there ! So - to recap

Engine Stopped - Trottle closed - fuel rack pulled to max position - with a very weak spring tension. Start engine - Engine rpm forces governor weights to force fuel rack toward closed - weak spring tension can just stop it closing completely - Idle speed. Give it throttle - adds spring tension to main spring - governor less able to close fuel off / rpms go up. Balancing act between the two ! - rpm's drop, spring forces more fuel - more rpm - weights force rack to close - more thottle = more sping tension - less throttle less spring tension. At idle - engine stop removes all spring tension - weights force fuel rack off. As soon as engine stops - and stop is released, weak spring tension is restored - fully opening fuel rack again, up against the max fuel limiter stop screw. I used to have model boats driven by elastic bands - I never thought I would actually sail in one !

Put text in individual divs |